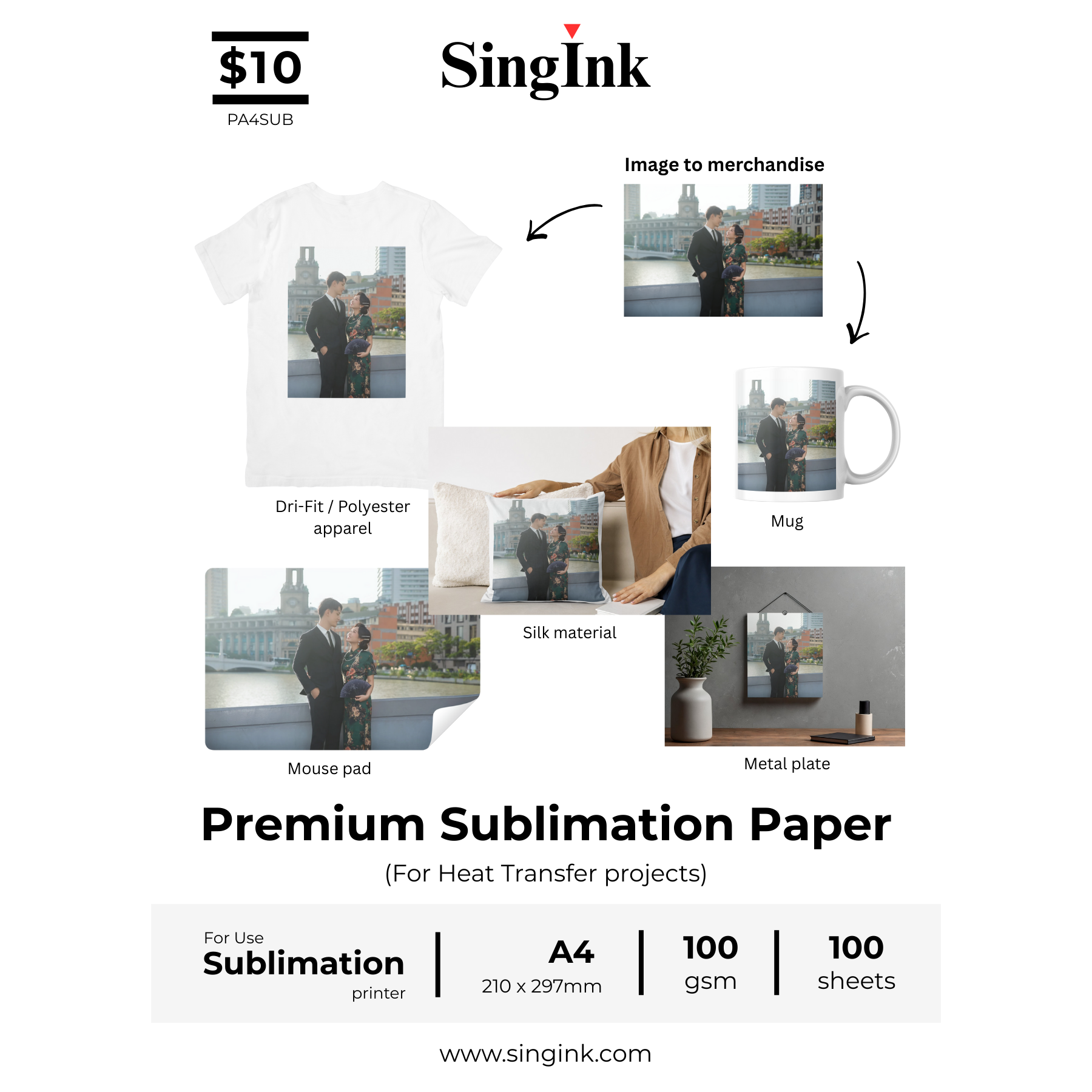

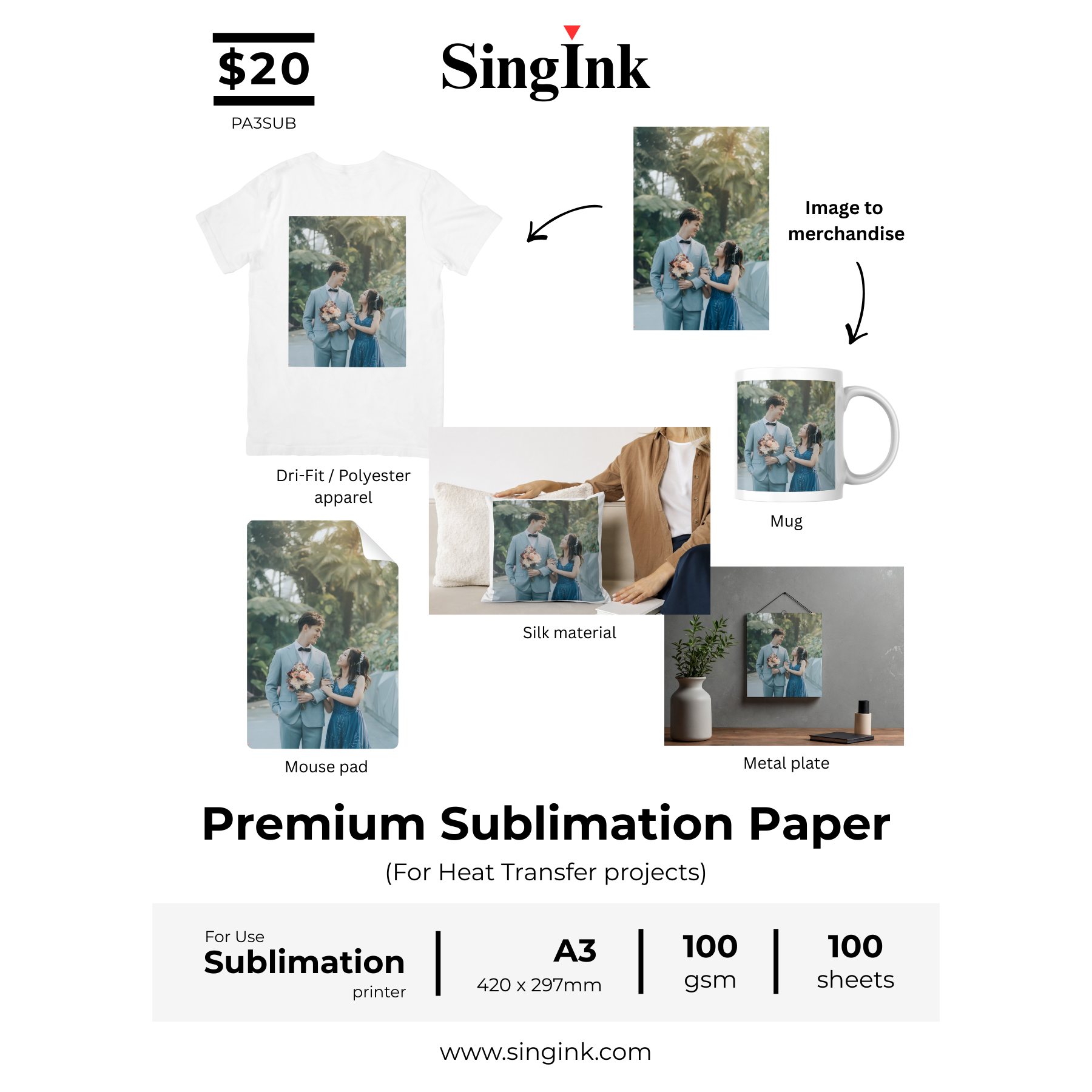

Sublimation Heat Transfer Paper – High-Quality Transfer for Vibrant Prints

Achieve vibrant, permanent, and professional sublimation transfers with our Sublimation Heat Transfer Paper, specially designed for dye-sublimation ink printing. This paper ensures excellent ink release, sharp details, and consistent colour transfer when used with a heat press.

Once transferred, the design becomes part of the material itself — no peeling, cracking, or fading. Ideal for apparel, hard surfaces, and personalised products, this sublimation paper is trusted by print shops, small businesses, and DIY creators.

⚠️ Important:

This paper is for sublimation ink printers only and works best on polyester or polymer-coated substrates.

Key Features

High ink transfer efficiency for vibrant colours

Sharp details with minimal ghosting

Fast drying surface for clean handling

Compatible with flat heat press & mug press

Suitable for light-coloured substrates only

Designed for sublimation dye ink use

Compatible Materials

Polyester & dri-fit fabrics (white or light colours)

Polymer-coated ceramic tiles & mugs

Aluminium sublimation metal sheets

Sublimation-coated hard surfaces

Best Practices & Tips

Always use light-coloured substrates

Do not use on cotton or dark fabrics

Store paper in a dry, cool environment

Test press settings before bulk production

Use protective paper to avoid ink transfer onto heat press

Ideal For

Custom apparel & sportswear printing

Personalised tiles, plaques & signage

Aluminium photo panels & wall art

Small business sublimation production

DIY personalised gifts

🔥 Step-by-Step Sublimation Tutorial Guide

1️⃣ Polyester / Dri-Fit Apparel (T-Shirts, Jerseys, Sportswear)

Recommended Fabric:

≥ 65% polyester (best results on 100% polyester), white or light colours

Steps:

Design your artwork and mirror the image before printing

Print onto sublimation paper using sublimation ink

Pre-press garment for 5 seconds to remove moisture

Place printed paper ink-side down on the fabric

Secure with heat tape if needed

Heat press at:

190–205°C

30–40 seconds

Medium pressure

Peel paper off immediately while hot

Allow garment to cool before handling

✅ Result: Soft, breathable print with no texture or cracking

2️⃣ Ceramic Tiles (Polymer-Coated Only)

Recommended Tile:

Sublimation-coated ceramic tile (white or light surface)

Steps:

Mirror artwork before printing

Print using sublimation ink on transfer paper

Clean tile surface to remove dust

Place paper ink-side down on tile

Secure with heat tape

Heat press at:

190–200°C

300–360 seconds (5–6 minutes)

Medium pressure

Remove paper carefully after pressing

Let tile cool completely

✅ Result: Vibrant, glossy image permanently embedded into the coating

3️⃣ Aluminium Metal Sheets (Sublimation Coated)

Recommended Material:

Sublimation-coated aluminium photo panels

Steps:

Mirror the image before printing

Print onto sublimation paper

Clean metal surface with a lint-free cloth

Place paper ink-side down on the metal sheet

Secure firmly with heat tape

Heat press at:

190–205°C

60–90 seconds

Medium to firm pressure

Remove paper immediately after pressing

Allow panel to cool

✅ Result: High-definition, durable print with vibrant colours and excellent durability